At GSC, we redefine industrial inspection through drone-based, AI-assisted aerial and confined-space technologies that deliver actionable insights while keeping your workforce out of harm’s way.

Our multi-industry inspection solutions are designed to minimize downtime, enhance asset reliability, and optimize operational safety — all while providing precise, data-driven results.

Smart Aerial Inspection. Safer, Faster, and More Accurate.

Flare Stack Inspection

Live without shutdowns

GSC provides unmatched visual access to hard-to-reach flare stacks using high-grade UAV cameras operated by our certified pilots.

We conduct live flare stack inspections while plants remain fully operational, capturing high-definition visuals that reveal the condition, performance, and integrity of your flare system.

This approach helps clients avoid costly shutdowns or unplanned flaring, ensuring safety and compliance while maintaining production continuity.

- Full-360 degree perspective of the asset

- High-resolution images

- Thermal images

- Inspection reports

- Onshore and offshore capability

Confined Space Inspection

Where humans can’t reach, our drones can.

Where humans can’t reach, our drones can.

At GSC, we deploy the Elios 3, the world’s most advanced indoor inspection drone, to safely explore confined, hazardous, or structurally complex environments.

The Elios 3 enables our team to capture high-precision visual and spatial data in areas that are dangerous or inaccessible for human entry — turning every mission into a fast, accurate, and risk-free operation.

With its intelligent navigation, LiDAR mapping, and obstacle-avoidance system, Elios 3 ensures exceptional stability and data quality, even in tight or dark spaces such as tanks, boilers, tunnels, and silos.

Benefits:

- Enhanced Safety: Eliminates the need for personnel to physically enter confined or hazardous areas.

- Reduced Downtime: Inspections can be conducted rapidly without shutting down operations or erecting scaffolding.

- Cost Efficiency: Minimizes rope access, scaffolding, and manual inspection costs.

- High Accuracy: Captures high-resolution visual and 3D data for detailed analysis and reporting.

- Instant Insights: Delivers real-time video feeds and immediate post-flight analytics.

- Regulatory Compliance: Supports documentation for safety and maintenance standards.

Industries We Serve:

- Oil & Gas

- Power Generation

- Mining

- Chemical & Petrochemical

- Infrastructure & Utilities

- Maritime

- Public Safety & Civil Defense

- Water & Wastewater

- Food & Beverage

Ultrasonic (UT) Inspection

Beyond visual — structural integrity in real-time.

GSC provides unmatched visual access to hard-to-reach flare stacks using high-grade UAV cameras operated by our certified pilots.

We conduct live flare stack inspections while plants remain fully operational, capturing high-definition visuals that reveal the condition, performance, and integrity of your flare system.

This approach helps clients avoid costly shutdowns or unplanned flaring, ensuring safety and compliance while maintaining production continuity.

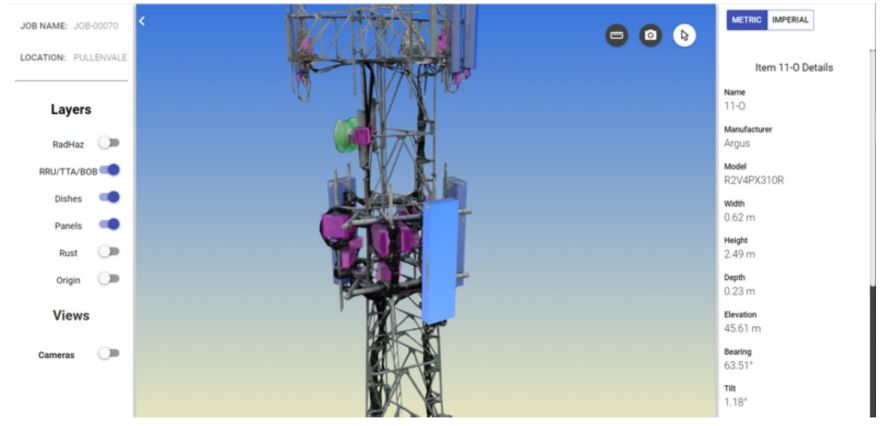

Cloud Inspection Data Platform

Your inspection data — centralized, visualized, and accessible.

All inspection data is managed through GSC’s cloud-based digital platform, providing seamless access to all visual, thermal, and measurement records.

Platform Features:

- Fully cloud-hosted inspection database

- 2D and 3D “Digital Twin” visualization

- API653 and API510 compliance

- Role-based access for asset owners, inspectors, and UAV operators

- Annotation and measurement tools

- Integration with 3rd-party systems

- AI-powered analytics and object detection

This digital workflow transforms inspections from static reports into interactive asset intelligence.

Confined UT Inspections

When precision meets safety.

Our Confined UT (Ultrasonic Testing) Inspection service combines drone technology with advanced non-destructive testing (NDT) methods to deliver comprehensive integrity assessments — even in spaces that are difficult or unsafe for human entry.

Using specialized drones equipped with UT gauges, we can perform thickness measurements, coating inspections, and corrosion assessments across complex industrial structures — without scaffolding, rope access, or production shutdowns.

Our system captures ultrasonic readings in real-time while simultaneously conducting visual inspections (VT) and close-up analysis, ensuring both structural soundness and surface condition are documented in one integrated workflow.

Applications:

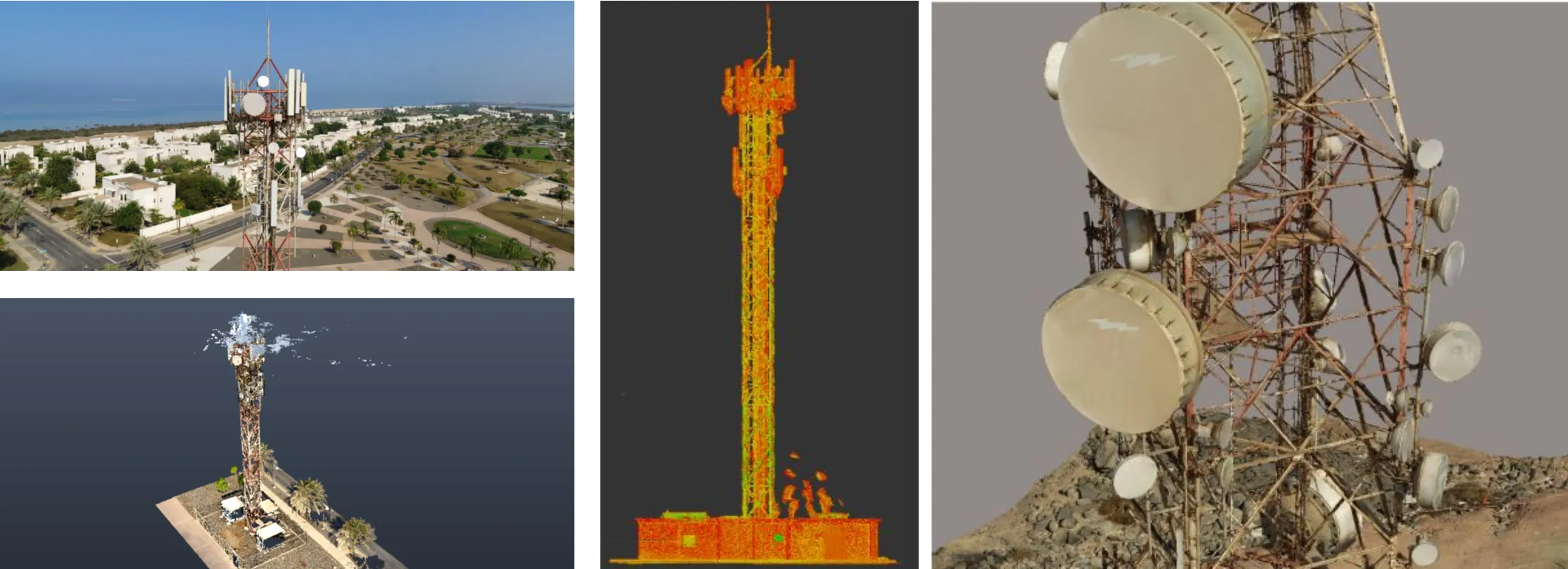

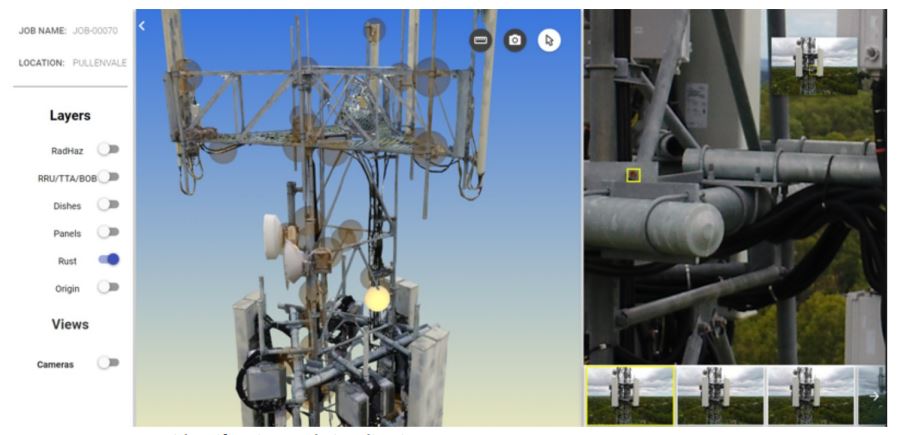

Telecom Tower Inspection

Precision mapping for vertical infrastructure.

Our drones capture geotagged, high-resolution RGB imagery and 3D point clouds of telecom towers, providing detailed insight into structural integrity and asset condition.

Delivered Reports Include:

- 3D As-Built Tower Analysis Report

- Rust Analysis Report

- Missing Bolt Anomalies Report

- Anomalies Report

- Empty Antenna Mounts Report

- Indicative EME Report

Through our web application, clients can access:

- 3D Mesh Model & Photo Navigation

- Orthomosaic View in 2D

- Panorama x2

These tools enable engineering teams to assess asset condition remotely and plan maintenance efficiently.

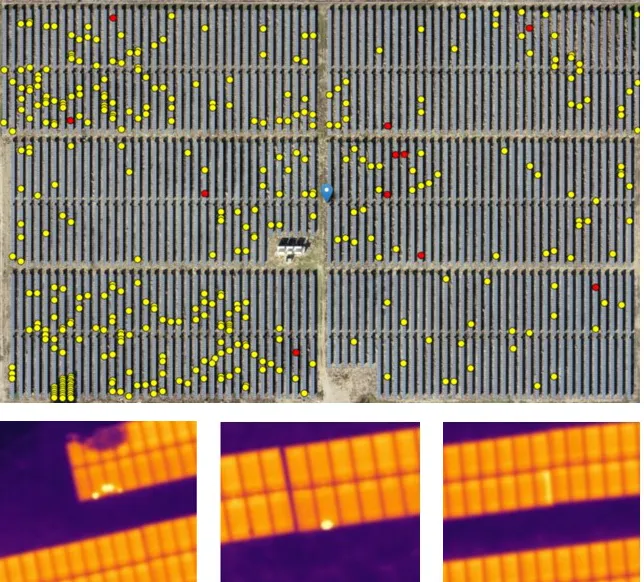

Solar Inspection

Thermal Inspection

GSC leverages AI-powered thermal and RGB drone sensors to identify solar cell defects in both ground-mounted and rooftop installations.

Our machine learning algorithms automatically classify anomalies, generating automated inspection reports that rank defects by severity — ensuring rapid diagnostics and reduced downtime.

Electroluminescent Testing Advantages

Electroluminescent (EL) imaging is a powerful diagnostic tool that provides deep insights into the health and performance of photovoltaic (PV) panels. By detecting internal defects invisible to the naked eye, EL inspection helps ensure system reliability and optimal energy output.

Plays a critical role in:

- Quality Assurance: Ensuring proper installation and performance during new PV plant commissioning.

- Yield Optimization: Identifying underperforming panels that contribute to energy loss.

- Targeted Maintenance: Pinpointing the exact type and location of defects to guide efficient maintenance and repair strategies

Rooftop Solar Panel Installation

Maximizing sunlight, maximizing efficiency.

At GSC, we deliver high-precision 2D CAD surveys that analyze the angle, length, and depth of shadows cast by every rooftop element — ensuring solar panels are positioned for maximum exposure and optimal energy generation.

Our experts use a custom-developed command tool integrated with Autodesk Civil3D, designed to automatically generate 3D polylines from point cloud data, accurately representing the height and projection of every rooftop structure.

This advanced tool also simulates sunshade movement throughout the year, enabling us to identify the deepest and longest shadow projections and record them directly on the CAD drawings.

Each survey includes detailed documentation of shade direction, spread, and absolute height measurements for all rooftop components — providing installers with precise data to optimize panel placement and overall system performance.

Rooftop Inspection Outputs

Our rooftop inspection delivers a comprehensive set of high-precision data products designed to support accurate solar planning, engineering design, and structural assessment.

Included Outputs:

- High-Resolution Orthophoto (1 cm/pixel): Ultra-detailed aerial imagery providing a precise visual base for analysis.

- 3D Point Cloud and Photorealistic Mesh: Accurate spatial modeling for visualization and measurement.

- Complete CAD Topographical Survey (Civil3D Format): Detailed elevation and layout data ready for direct engineering integration.

- Spot Elevations: Reference points accurately tied to the building’s control base.

- Labeled Feature Heights: Heights of rooftop elements such as walls, parapets, HVAC units, and other features clearly annotated.

- Calculated Roof Slope Grading: Accurate slope mapping to assess drainage and panel alignment potential.

- Detailed 3D CAD Drawings: Precise representation of all rooftop features and surfaces.

-

Annual Sun Path Simulation: Shading profiles accurately reflect the sun’s movement throughout the entire year.

-

Daily Shadow Projection: Simulated shadow casting from sunrise to sunset for complete daylight analysis.

-

Custom Time-Based Simulation: Ability to visualize and analyze exact shadow behavior for any selected time and date.

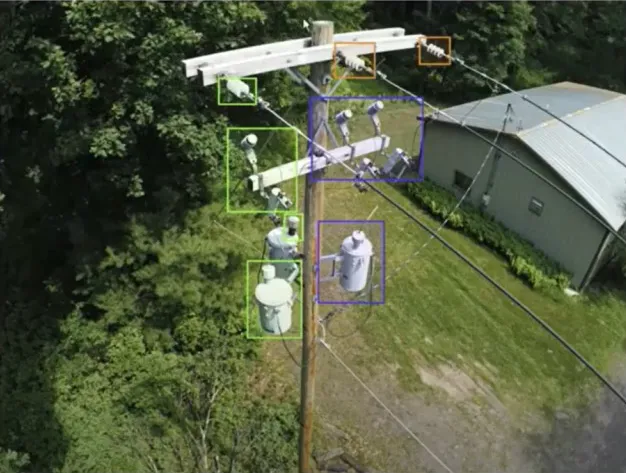

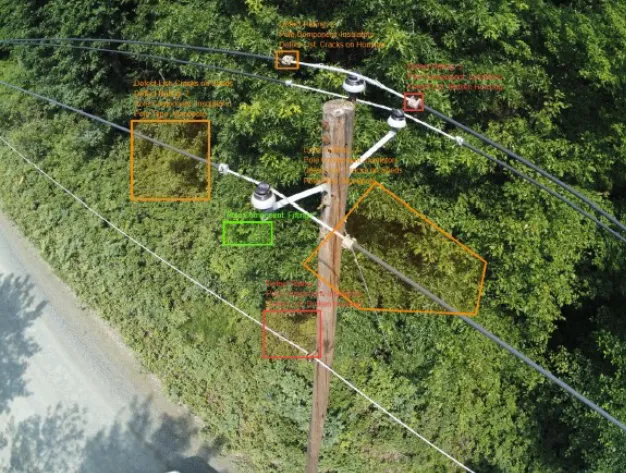

Powerline Inspection

At GSC, we deliver advanced drone-based inspection solutions for transmission towers and overhead power lines (OHL), providing utilities and energy operators with precise, actionable data that enhances safety, efficiency, and asset performance.

By leveraging high-resolution aerial imagery and AI-driven analytics, our inspections detect structural defects, component degradation, and potential hazards — all without interrupting operations or putting personnel at risk.

Tower Components Inspected:

We conduct thorough inspections of all critical parts of each tower, including:

- Bottom, middle, and top crossarms

- Optical Ground Wire (OPGW)

- Marking lights, warning spheres, and spacers

- Supporting connectors and tower joints

Key Benefits:

- Enhanced Safety: Eliminates the need for climbing or manual inspection in high-risk environments.

- Reduced Time & Cost: Rapid data collection significantly lowers inspection time and labor requirements.

- Access to Remote Areas: Drones easily reach towers and lines in difficult or inaccessible terrain.

- High Accuracy: Captures detailed visual and measurement data with centimeter-level precision.

- Streamlined Workflow: Simplifies inspection planning, execution, and reporting through automated processing.

AI-Powered Data Analysis:

We utilize industry-specific AI models developed by power infrastructure experts to automatically process drone-captured data and detect anomalies.

For every tower inspected, our AI platform generates:

- Precise Geographical Location

- Tower Type and Component Classification

- Detailed Defect List with Severity Ratings

- High-Resolution Images Annotated with Defect Overlays